Fully Automated

Semi-Automated

Operator-Driven

About us

KITO U.S.A. is a subsidiary of KITO MACHINE INDUSTRY CO, LTD, a Japanese corporation that has been operating in the world of equipment manufacturing for the automotive industry for nearly seven decades. We are proud of our strong heritage and the significant role we have played in the ever-evolving mechanization of automobile manufacturing.

KITO U.S.A. is a strong corporate citizen, headquartered in Lexington, Kentucky, and our employees always rise to the challenges of consistently meeting and exceeding the expectations of our customers.

We have developed a unique approach to system design, manufacturing, installation and support through the development of our own cutting-edge technology, earning KITO numerous awards through the years, and providing us with a prominent place in the world of automotive manufacturers.

Learn More

Our Products

What we offer

Design

The Design process at KITO U.S.A. involves close collaboration between the team at KITO and our client. It is critical that we design to the exacting specifications of our clients.

Fabrication

In-house fabrication and machining teams can manufacture high tolerance specifications with welding, 3-5 axis milling, and lathe applications, all the while meeting critical deadlines.

Machining

KITO U.S.A. has achieved its successes through the years by continuously researching and investing in cutting-edge equipment and materials for machining that enable us to perform at our best for our valued customers.

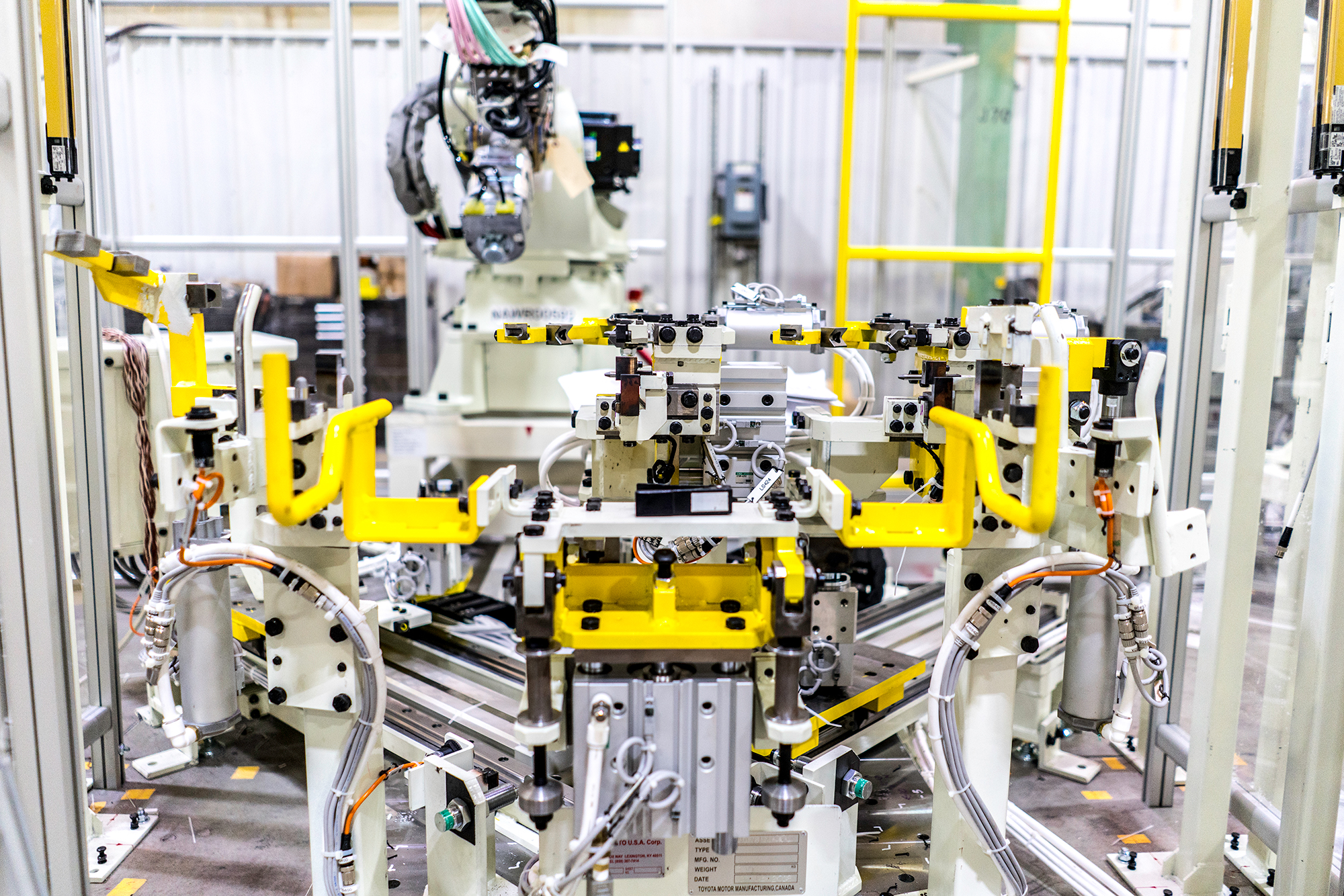

Mechanical Assembly

Mechanical Assembly goes to the heart of what we do for our clients. KITO U.S.A. is the leader in superior body welding equipment build, installation and support.

Electrical Controls

KITO U.S.A. values our clients, their expertise and their goals and will work side-by-side with our clients to develop an electrical design that will best serve the needs of their equipment and production goals.

Sales

Consult with the Sales team at KITO U.S.A. for more information on how we can partner with your company to take your automotive manufacturing system from design to finish.